Bar Bending Machine Pdf

Norton Machine Design Prentice Hall 1996 It is assumed that the correction for the mass of the struck bar reduces the efficiency to η. In order to search the specific IS book enter the code number Ex.

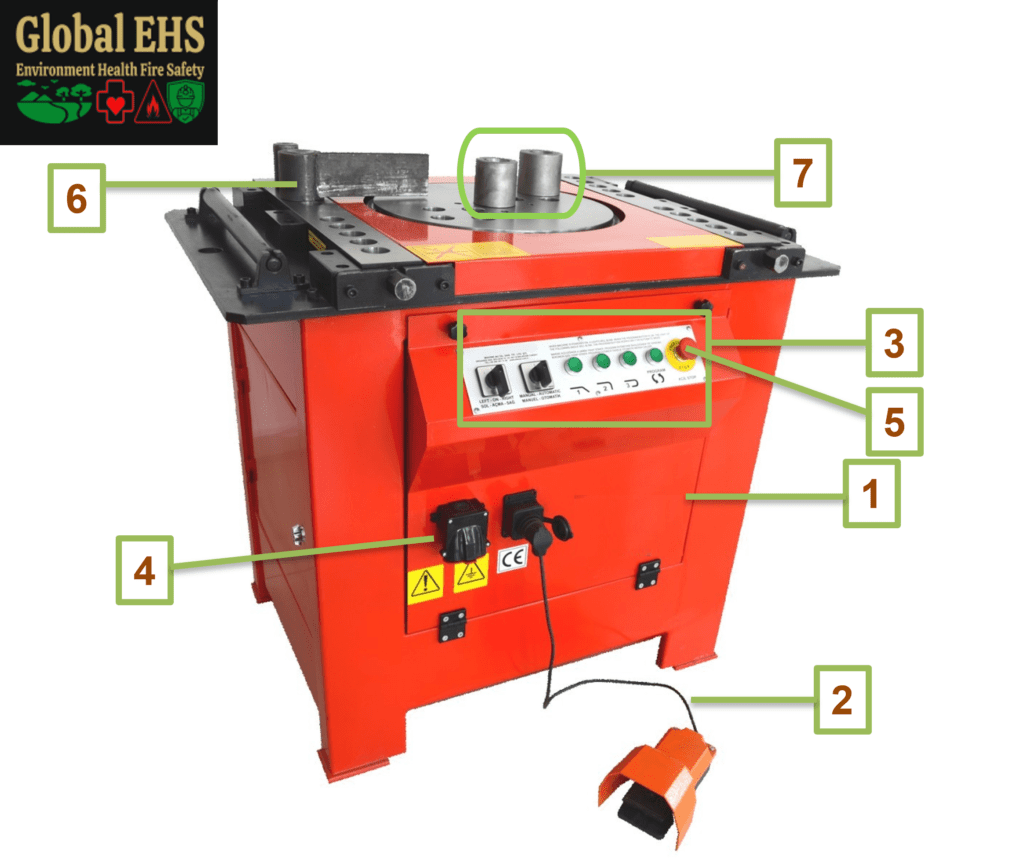

Bar Bending Machine Safety Inspection Checklist

The second example models a 1 kg mass moving horizontally along a steel E 207 GPa bar 100 mm long with a 10 mm diameter and striking the end of the bar with a velocity of 1 msec.

. Unbraced column- where the lateral loads are resisted by the bending action of the column. Due to the possibility to retrofit an optional second bending direction TopBend at a later date the EcoBend entrance-level machine for one bending direction represents a secure investment in the long term. The Centerline Ball Bar Ranger is actually a revision of a fifteen year old product.

Arab Emirates is the one best Industrial Safety Equipment Dealers we offer Power Tool Accessories Cutting And Milling Tools Cutting Grinding Tools Abrasive Tools In Dubai UAE. This dramatic improvement reduces the effect of any sag or bending of the bar to an infinitesimal second order cosine. Problems 1-1 through 1-4 are for student research.

σ0 Mc l where c d2 and I πd464. Download Free PDF Download PDF Download Free PDF View PDF. In fact the answers to all these questions are the same.

Figure A1515 Grooved round bar in torsion. Main Parts and Its Working Principle. 1030 Mechanical Engineering Design Figure A1513 Grooved round bar in tension.

Simply put a press brake is a piece of equipment used to complete the bending and forming of the sheet metal. A performance-optimized design and unique bending kinematics enables very high operating speeds for series production. Machine shop notespdf 1.

If you do want to know the definition of press brake you can read the article below to learn more details about the history of the phrase press brake and why it is been called that way. A very important change from the old version of the Ball Bar Ranger puts the SMRs right on the neutral bending plane of the Ball Bar. To avoid the bending of the workpiece due to the cutting forces acting by the tool exactly opposite to the tool support is provided and it is moving along with the tool called as follower rest.

Download Free PDF Download PDF Download Free PDF View PDF. The tapered bar of the lathe machine can be set with different angles to the spindle axis. Boschert a global leader in punching- cutting- and.

Reprinted with permission from Machine Design a Penton Media Inc. This is mainly due to the workpiece bending up movement hit the back stopper and was squeezed which lead to the deformation. Pull-back the back gauge.

The most common shapes are round circular cross-section rectangular square and hexagonal. SIWES REPORT BY TUNDE OYEDOTUN VICTO R 12BCOO1914 GEC 429 Page 42 From BS code 81101997 clause 3815. Bar stock is available in a variety of extrusion shapes and lengths.

Download Free PDF Download PDF Download Free PDF View PDF. The best part of this post is you can view and download the all Civil engineering IS-code books in PDF. For long work the bar is supported on the spindle end and on the column bearing block.

Boschert USA is the exclusive North American representative of technologically advanced European fabricating machine lines from Boschert GmbH Stierli-Bieger PBT Boschert Gizelis and AMB Picot. A bar is characterised by an enclosed invariant. 456 dont include the IS before the code number in search.

σ0 FA where A πd24. It is placed at some intermediate point to prevent the work piece from bending due to its own weight and vibrations setup due to the cutting force. When bending Z shape by CNC bending machine some parts will be deformed.

Bending size is small bad positioning the mold is easy to press the back gauge. The boring bar supports the cutter for holding operations on jobs having large bore diameters. τ0 Tc.

Bar stock also colloquially known as blank slug or billet is a common form of raw purified metal used by industry to manufacture metal parts and products. Arrange the tools as specified above from the. For short holes the bar may support on the headstock spindle end only.

Use the search bar on the table to find the specific IS codebook as per your requirement. Copper bar processing punch-plasma punch-laser and flatbed fiber laser cutting machines. It is taken from RL.

Figure A1514 Grooved round bar in bending. A link connects the sliding block to the cross slide. Procedure Cut mild steel rod of 25mm Ø in 125mm length from long bar by using power hack saw or ordinary hack saw.

Safetyforall01 Bar Bending Machine Checklist Facebook

02 Bar Bending Machine Pdf Drl Project Check List For Bar Bending Machine Project Name Equipment No Contractor Name Inspection Date Equipment Course Hero

Bar Bending Machine How Does It Work And How To Operate

4 Kinds Rebar Bending Machine How To Use Them

Bar Cutting Bending Machine Steel Bar Bending Machine Manufacturer From Ahmedabad

Bending Machine Mod P42 3 Phase Simpedil Srl Pdf Catalogs Technical Documentation Brochure

Comments

Post a Comment